Inventing the Lovelace Engine

The Composer and Inventor behind the Lovelace Engine take you from brainstorm to stage

15 May 2020

Jonathan Morris (left) and Robert Laidlow (right) with the Lovelace Engine at the premiere of Alter

Introduction

On 2 November 2019, the first PRiSM Commission, Alter, premiered at the event Ada Lovelace: Imagining the Analytical Engine, part of Barbican’s Life Rewired series. This was an evening of new music and discussion inspired by the life and work of Ada Lovelace, an early pioneer of the computer. A talking point was the extraordinary machine on stage: The Lovelace Engine.

In this article composer Robert Laidlow and inventor Jonathan Morris take you through some of the challenges, solutions and joys involved in bringing this musical instrument from brainstorm to stage.

They focus on the design and implementation of two of its key elements: the rhythmic ‘number’ cylinders, arrayed in columns, and the ‘steam’ generation. They also touch on the less visually apparent but crucial consideration of its hardiness, and ability to stand up to the stress of transportation, performance and rehearsal.

Inventing the Lovelace Engine

By Robert Laidlow (composer) & Jonathan Morris (inventor)

The Lovelace Engine was designed to be performed in the first PRiSM Commission, Alter, premiered at the event Ada Lovelace: Imagining the Analytical Engine, part of Barbican’s Life Rewired series. The event focussed on Ada Lovelace and her imaginative theories on how Charles Babbage’s Analytical Engine might be utilised. During the composition of Alter, we brought together experts from many fields – music, computer science, history, engineering – in the same way that Lovelace herself brought together her expertise across disciplines to inform her work. An early idea we pursued was that of creating a new instrument with modern technology, inspired by Lovelace, Babbage and the Analytical Engine.

The Lovelace Engine on stage at Milton Court during the world premiere of Alter performed by Marta Fontanals-Simmons, Britten Sinfonia conducted by William Cole

Cylinders

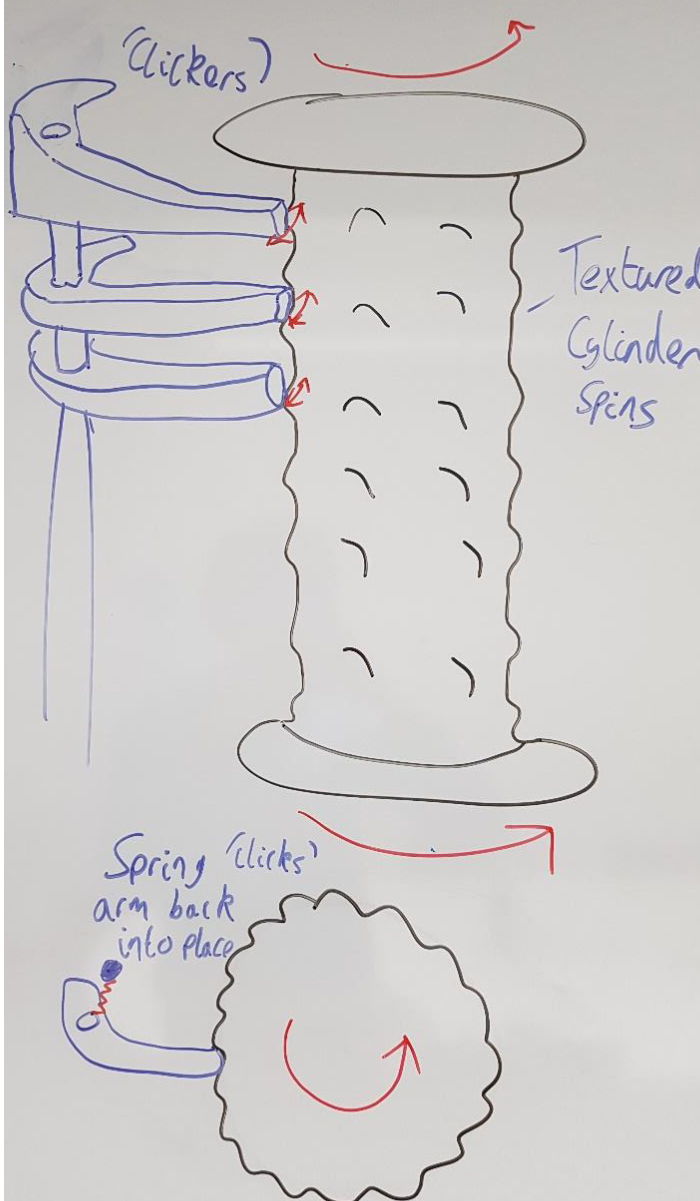

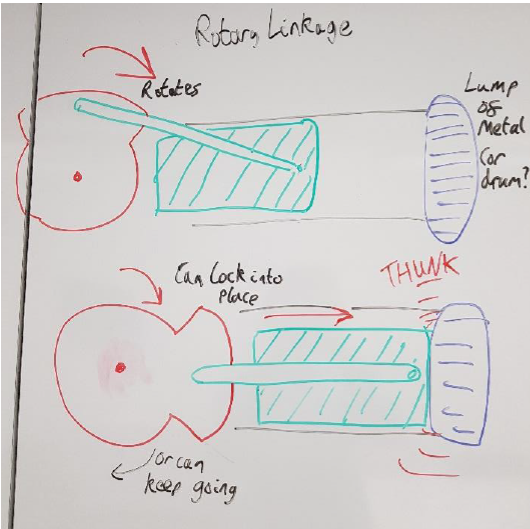

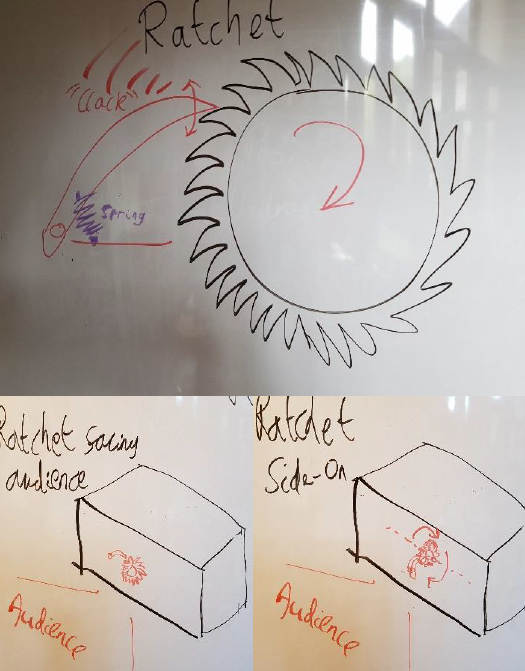

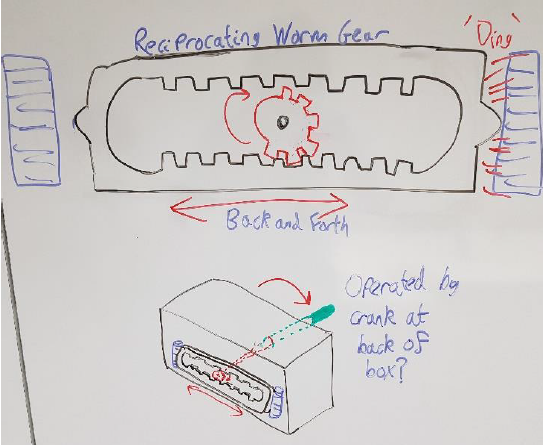

The principal sonic components of the Lovelace Engine are its characteristic cylinders which take up much of the facade. We were inspired by the noise made when Babbage’s Difference Engine is operated (you can hear a working recreation here). The sound that emerges from the interlocking counting columns is loud, sharp and unrelenting, almost a piece of music in itself. As taken as we were by this, we wondered if we might also be able to create more precise, notable rhythms with our Lovelace Engine.We settled on creating three columns of rotating cylinders, each of which could produce a specific subdivision of the crotchet beat, and each of which could be armed or disarmed during the piece to facilitate combinations of cross-rhythms.

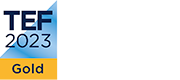

These cylinder stacks would divide the beat into three, four and five – so they would sound as triplet quavers, semiquavers and quintuplet semiquavers if the machine was “in sync” with the ensemble – that is, if the percussionist’s arm moves in time with the counting of the players. This last point is particularly important – one entire turn of the manual crank that powers the Engine is counted as four beats for the purposes of the components’ rhythms (see table below).

If one entire turn of the crank is faster or slower than the players count four beats the Engine will be out of phase with the ensemble. This is a feature that is a necessary result of the Engine’s design, but was exploited deliberately at several points during Alter, as the instruments of the ensemble drift in and out of focus with one another.

Initial brainstorm ideas for the ‘cylinders’ of the Engine

Writing for a percussionist to manipulate these cylinders during a performance introduced some musical challenges. For example, in considering how to exploit the sound of the cylinders turning, without it becoming wearing on the ear. Since the cylinders have only one timbre, we decided that the solution must lie in varying rhythmic and stylistic approaches to the writing.

Table to match desired musical cross-rhythms with internal gear ratios

During some parts of Alter, the Engine plays a steady, unchanging rhythm, a grid upon which the other ensemble instruments are superimposed. In others, it performs dramatic interjections, where the duration of the interjection is more important than the internal rhythm of the cylinders. Here, the focus for the performer switches from maintaining a steady beat – moving the crank at a constant speed – to making sure the sound stops and starts at the correct time – which requires control of the mechanism in a different way.

Watch the cylinders of the Lovelace Engine from prototype to performance.

Half-way through the piece, the Engine accompanies a vocal and electronic duet. There is dialogue between the mezzo-soprano, the electronics track and the Engine – each responding to the other. The performer of the Engine is free to create an atmosphere of tension, with absolute control over each individual “click”. The section is very quiet, giving the performer full jurisdiction over how many cylinders to engage to achieve the balance they feel is most appropriate for this moment. Interestingly, this approach to varying use of the Engine mirrors an issue found with some of the music-generating artificial intelligence networks used in the composition of Alter: they provide striking pitch and rhythmic content, but no timbral information.

Steam

From the very first sketches of the Engine, a key priority was to ground the project in authentic, Victorian design principles which would have been familiar to Lovelace and her contemporaries. Traces of Wheatstone’s electric telegraph, Jacquard’s automated loom and Babbage’s own Difference Engine can all be seen in the Lovelace Engine, alongside the fundamentally mechanical operation of the machine.

To capture the innovative spirit of the age however, one element remained missing; steam. If Lovelace herself had imagined the future of computing, it is more than likely that it would have been steam-powered, yet the challenge of incorporating a functioning steam engine into a musical performance (as well as the fire regulations of one of London’s premier music venues) all but prohibited its use in the Engine. Our challenge was to innovate and convey this idea in a realistic way.

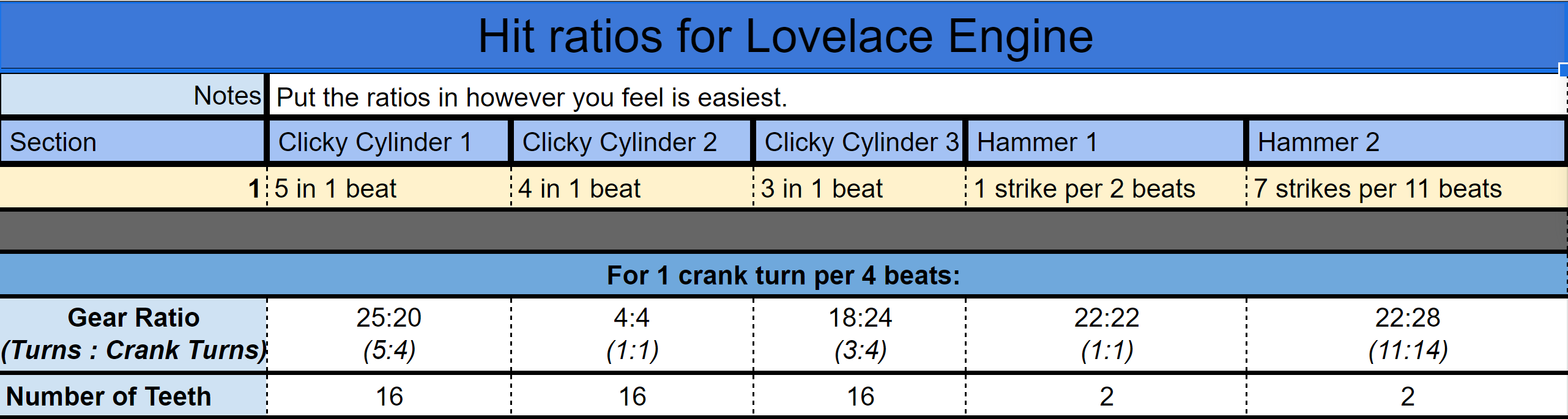

As with all other elements of the Engine design, the solution began with a sketch. By generating many varied initial sketches, we had a wide selection of potential avenues to solve the problem. One such sketch considered simulating the ‘hiss’ of steam by releasing compressed air from a can.

Simple sketch from the initial design process. All concepts were evaluated based on their merits, technical risks and difficulty to produce, before a select few were brought forward into the final design

Often the quickest way to validate whether an idea on paper will work is to build a quick prototype, which is exactly what we did. Prototyping is a hugely useful tool for any designer, as it allows quick insights into a problem and reveals challenges and intricacies which are hard to tease out of a quick sketch. To prototype this idea in its simplest form we used a standard compressed air can, making a note of the sound it made when activated using a mechanical switch.

Steam from a can: from sketch to prototype

Watch the simplest first prototype of the ‘spray can’ concept.

This initial result worked but lacked the sense of theatre that we felt the Engine needed to capture the audience’s imagination. Experimenting with this simple mock-up, however, we found something that would never have become apparent with a sketch. When used at an angle, the spray can would vent its propellant, which would very quickly boil into a vapour in a dramatic rush.

Watch a revelatory moment in the Engine’s design; the realisation that we could generate ‘steam’ on demand using compressed air.

This was precisely the sound and imagery we were looking for, as well as being easy to control and safe for the performers and audience. By considering a broad range of ideas and playing with crude prototypes, we had found the centrepiece for the Engine’s performance. A more robust prototype was made to see how this idea could be integrated into the piece. This allowed us to investigate how quickly the performer could conjure the ‘steam’, how much was available to us (which influenced the composition of the piece), and how it would look against the backdrop of a concert hall.

Watch testing of the second ‘steam’ prototype. Thanks to rapid prototyping techniques such as laser cutting, this prototype was created in less than a day.

Performing a ‘test run’ of the steam system. With its workings now obscured to the audience, the theatrical illusion is complete

Iterating twice on the design also provided valuable learnings about how to integrate the steam into the complete Engine, and many elements of this second prototype were used in the final build. Committing time early on in the design resulted in the faster overall development of this part of the Engine. When tested as part of the whole assembly, the results were spectacular – a real showstopper.

The Lovelace Engine in action at the concert, bringing the notion of a steam-powered computer to life.

In addition to the visual experience, the ‘steam’ also provided an interesting and rich sonic timbre to be exploited as part of the musical palette of Alter. As this sonority was such a contrast to the rest of the Engine’s battery, we decided to give the ‘steam’ a solo moment amongst the industrious instrumental parts surrounding it. To accentuate this sense of unexpected juxtaposition, and for the practical reason of conserving gas, we opted to trigger the ‘steam’ only once in the piece – and were very happy with the surprised and delighted response at this moment from the audience. Pausing the ensemble while the ‘steam’ vents was also a useful way of reinforcing the notion that the music and the Engine are intertwined, which was important for the overall narrative of the work. When the Engine is venting, the ensemble cannot play.

Reliability

Development of the Lovelace Engine presented many varied technical challenges, but all essentially amounting to the same goal; on 2nd November 2019, it had to work flawlessly for 12 minutes, on stage, to a packed audience. Once on stage the Engine could only be operated and accessed by the performers. They had enough to rehearse without training as amateur mechanics; reliability was to be a critical part of success for this project.

With this in mind, we did everything we could to ensure the design was accessible and repairable right up until the last minute. This ranged from scheduling a maintenance session on the morning of the concert, to using the same sized bolts throughout to ensure we always had the right size Allen key – if it worked for Ikea, it could work for us. Both of these proved worthwhile as the Engine was fully put through its paces during rehearsal, including a memorable moment where a sharply pulled lever caused a part of the contraption to hurtle across the room and break onto the floor. Staying in regular contact during the rehearsal process was also crucial, as it meant fixes could be made in parallel, and everything could be readied to make repairs on the day of the concert. While all of the core parts performed reliably, the modular design of the Engine also meant that if required, spare parts could have also been made available on the day, perhaps even 3D printed the night before.

Throughout all 12 minutes of its debut, the Lovelace Engine was expertly operated by the Britten Sinfonia with no failures. One of the most important factors responsible for this was the working relationship we established at the start of the project – we both shared the goal that the completion of the project was not the assembly of the machine, but the conclusion of its performance.

Learnings

If we have learned anything from this project, it’s that the business of inventing and composing for a new instrument holds many more possibilities than we could have first imagined. There are, however, a few specific points that might save time for anyone attempting a similar project in the future.

The first relates to the crucial requirement for reliability. While we took steps to make maintenance simple, towards the end of the process it became clear that we were up against a feature inherent to the design of the Engine. As the entire machine was operated by a single crank, this meant that every part was interconnected, and therefore interdependent. If one cylinder refused to spin, then the rest of the Engine would simply not have run. To avoid this in future projects, focus should be placed in keeping systems separate, wherever possible, to avoid an ‘all-or-nothing’ level of functionality. This may require more inputs from the performer, but this is all the more reason for involving musicians at the earliest possible stages of design. Having multiple systems also allows for redundancy; if one part breaks in the middle of a performance, the performer still has agency over the remaining modules to continue the piece.

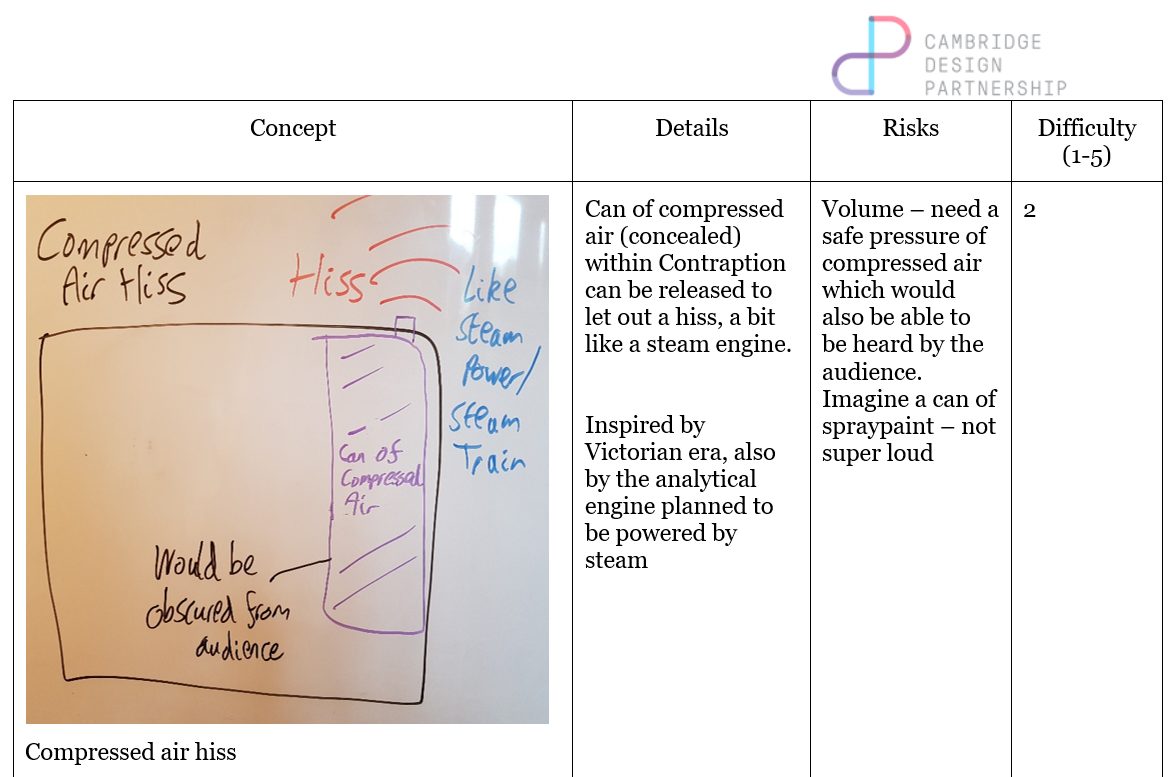

On the musical side, more could have been done to link the notation of the Engine and its mechanical capabilities – making sure that the design and capabilities of the Engine were communicated effectively to the performer. The notation of the Lovelace Engine’s part resembled closely a regular percussion part, following the logic that the part at least should be familiar, if the instrument is totally unfamiliar. However, this notation style did not allow for sufficient detail to be conveyed about the mechanical capabilities of the Engine. As a result, the contraption tended to be operated at the extremes of its intended range. For a future project, a notational system more like tablature – i.e. one that physically describes the instrumentalist’s actions, rather than one based on symbolic interpretation – might be more suitable.

An example of the notation employed in Alter to direct the Engine’s performer

The key lesson learned from tackling the multiple mechanical challenges was the value in sketching, building models, and ‘trying out’ as many ideas as we were able to, as part of a complete design process. Whilst it is easy to see time spent drawing and prototyping as a delay to working on the ‘actual’ design, without these simple early tests we would have missed out on one of the key features of the finished Engine and piece. This is an ethos that extended beyond our work on the Engine, encompassing all the members of the PRiSM team during the creation of Alter. Collaborations began well in advance of the work’s premiere, allowing the team to strike a useful balance between ‘top-down’ directed work, where we realised a set goal, and ‘bottom-up’ industry informed by free experimentation.

About the authors

Jonathan Morris is a Mechanical Engineer at Cambridge Design Partnership. Robert Laidlow is the PRiSM Researcher in AI-Assisted Composition at RNCM, in Association with the BBC Philharmonic Orchestra.

Jonathan Morris (left) and Robert Laidlow (right) with the Lovelace Engine at the premiere of Alter